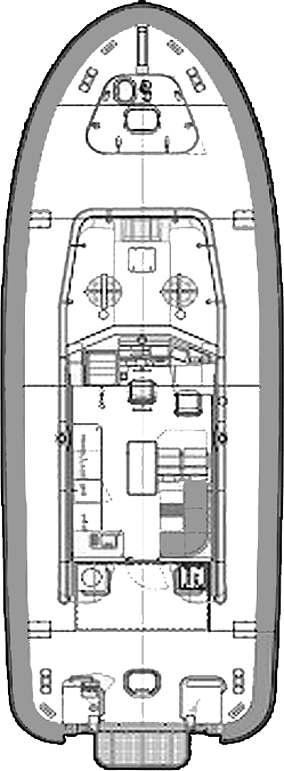

Boat RIB Design

Woody Marine Fabrication has a design service aspect to the business. Stephen Plummer is not only the director of WMF but is also a qualified Naval Architect allowing the clients to get custom designed rigid inflatable boat drawn up and built all in the one location. We feel that this ability to offer this service is very special and provides a personal touch with every boat rib.

Hull Design

The boat rib hull design is then generated in 3D in Maxsurf, a specific hull program that calculates critical hull parameters in order to design. We provide the client with 3D images in various orientations, giving the client a visual picture of how their boat will look before construction.

Concept

From the clients’ concept in initial discussions, we draw computer generated Cad plans for the basis of discussions. We have the ability to design either Commercial or Pleasure boats and to various classification society rules.

Computer Cutting

We can generate computer cutting files that our Aluminium supplier can use with their routing equipment, providing an accurate, efficient and cost effective means of building a rigid boats. This feature of the design office ensures the ability to build a boat of the highest quality and accuracy.

Project Management

With years of experience in the boating industry, we can build the boats as well as coordinating all the other trades required to get the boat from the drawing board to the water. We know various sub-contractors from marine electricians to marine engineers to carpenters to hydraulic engineers to upholsterers and painters. Once the boat rib is complete in the workshop, it is then sea trialed to ensure that all the systems work, from anchor winches to toilets to main engines and steering. The vessel is then commissioned and ready to be deliver to the client.